Unlike wind, Bio-fuels/mass is often less discussed and considered the high hanging fruit on the renewable energy tree. Overtime however, there has been a steady increase in the use of Bio-fuels for both economic reasons and for meeting the green directives. This article discusses the production of Bio-fuel in Scotland through edible oil.

The total consumption of edible oil around the world has seen a steady increase over the past few decades. As our taste buds are developing a craving for more acidic food, we are consuming more fried food than ever before. EU-27 consumes 23.5 million tonnes of vegetable oil with the world market being around 160 million metric tonnes an year. Data from Office for national statistics confirms that almost £9 million is spent on edible oil weekly by households in UK.

Unfortunately most of the oil, particularly used in households, is not disposed properly. In a recent program on the BBC, sewerage systems were shown clogged up with “Fatbergs” (Solid mass of fat that is a result of oil coagulation). These “Fatbergs” were several meters in length, weighed in tonnes and cost a fortune for removal. Closer to home, similar video showing fatbergs in highlands sewerage pipes was produced by Scottish Waters. This indeed is a growing problem for which awareness is being created through advert campaign to keep the sewerage lines running.

In Scotland, several domestic bio-diesel producing units are mushrooming. This is mainly due to increased awareness and soaring price of diesel. In most cases, unused vegetable oil can be directly used as fuel for a diesel engine without any treatment. In 2002, when the price of edible oil dropped to 42 pence a litre ( 30 pence cheaper than the regular diesel price at the time), people rushed to the superstores to fill up their fuel tanks. Most stores reported a spike in cooking oil sales along with the presence of empty bottles in the car park. Cooking oil is viscous compared to diesel sold at the pumps and this can be a problem during the winters as lower temperatures equate to higher viscosity. To address the issue, several kits are available on the internet that warm up the oil before it enters the engine.

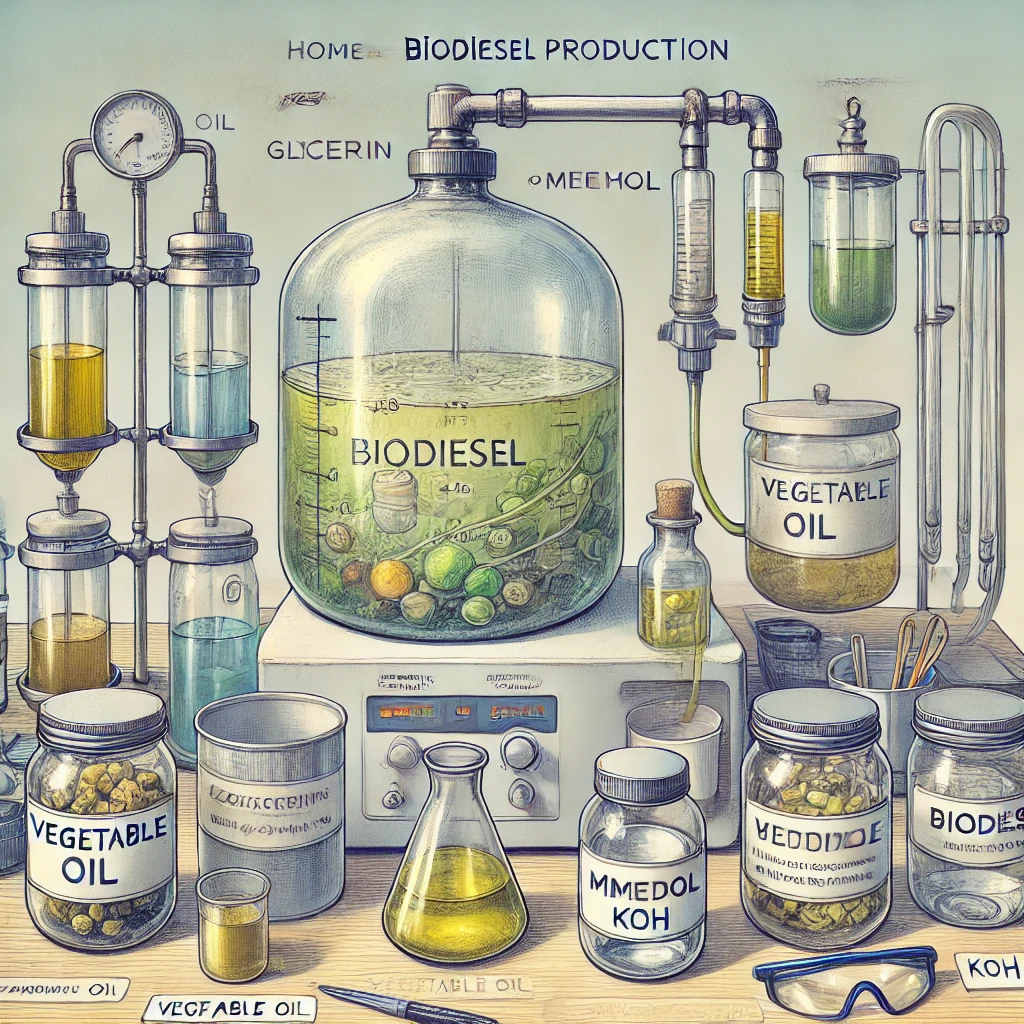

In addition to unused cooking oil, used cooking oil, which has additional free fatty acids, water and food particles, can also be filtered and processed into bio-diesel through recipes available on the internet. These recipes mainly involves the use of Lye (Sodium hydroxide) dissolved in methanol poured into the waste oil. The reaction is exothermic and precautions must be observed in handling chemicals and storage of the fuel. Several homemade processing kits (mini-plants) for producing bio-diesel through waste cooking oil can be purchased cheaply from websites like e-bay. Some of them are merely a barrel with a stirring apparatus. A tap at the bottom of the barrel is provided to drain the glycerin, that is produced as a by-product and accumlates at the bottom. For a higher price, more sophisticated equipment can be purchased which may include more than one storage tank, a pump and a motor to stir the Lye-methonal mixture.

Diesel through waste chippy oil sounds like a win –win situation as restaurants/ takeaways are happy to dispose their waste oil for free, Scottish waters would appreciate clear pipes and people would like cheap fuel. And it has been a success for Glasgow based “Apple Fuels” who have seen their business grow over time, providing their customers with cheaper than market fuel and in the process helping out the environment. The government had a tax differential on bio-fuels that kept them at least 20 pence cheaper than fuel at the pumps. From 1st April 2010 however, the duty on bio-fuels was increased to the same level as conventional petrol and diesel. This increase in duty is seemingly unfair on two counts. Firstly it reduces the profit margins for small bio-diesel producers. Secondly, the calorific value of bio-diesel is less than conventional diesel and so slightly lesser mileage is expected from it.

On an industrial scale “Argent Energy” of Motherwell are producing bio –diesel and have a capacity 50 million litres (45,000 tonnes) of high quality bio-diesel a year. They not only use waste cooking oil but also use waste animal fat.

A byproduct of bio-diesel is glycerine. This glycerine can be used to either create soaps (for which again several recipes are available) and can also used in anaerobic digesters. However, if this glycerine, is processed it can be turned into industrial grade glycerine, which sells for much higher price per ton compared to crude bio-glycerine. A wiped film evaporator is required for this value addition. In Scotland, Pfaudler produces these evaporators. Unfortunately the cost of it is prohibitive for a small scale producer.

Thus bio-fuel production through waste oil- from an environmental perspective- is an extremely healthy activity but to further this cottage industry, safety directives and guidelines must be issued by the authorities. The duty differential must be maintained to give the added incentive to small scale producer. Communal facilities, where wiped film evaporator is available should be provided so that it can be shared between several producers. Subsidy should be given if a producer wishes to purchase the evaporator. ROC’s can also be issued against a specific production volume. There are also calls from the industry to establish a Bio-Technology test facility, perhaps that can be also looked into.