Heat pumps have become pivotal in the global shift toward low-carbon heating and cooling solutions. By transferring heat rather than generating it through combustion, these systems can achieve efficiencies exceeding 300%, positioning them as a compelling alternative to traditional fossil fuel-based HVAC systems. However, conventional vapor-compression heat pumps depend on complex mechanical components and refrigerants with high global warming potential. This is where solid-state heat pumps, particularly those leveraging the elastocaloric effect, present a promising advancement—and a recent breakthrough by HKUST could significantly reshape the field.

Researchers at the School of Engineering of the Hong Kong University of Science and Technology (HKUST) have developed a novel elastic alloy, Ti₇₈Nb₂₂, which exhibits remarkable efficiency for solid-state heat pumping. This alloy demonstrates a reversible temperature change (ΔT) ability that is 20 times greater than that of conventional metals when subjected to mechanical stress, offering a promising green alternative to traditional vapor-compression heating and cooling technologies.

What sets this material apart is its stretchable, high-elastic behavior, allowing it to undergo large, reversible deformations without structural fatigue. Unlike conventional shape memory alloys that depend on internal phase transformations involving friction and wear, the Ti₇₈Nb₂₂ alloy leverages smooth lattice distortions to generate thermal shifts. This allows the alloy to absorb and release heat efficiently during mechanical stretching and relaxation, enhancing both durability and thermal responsiveness—two critical parameters for real-world performance.

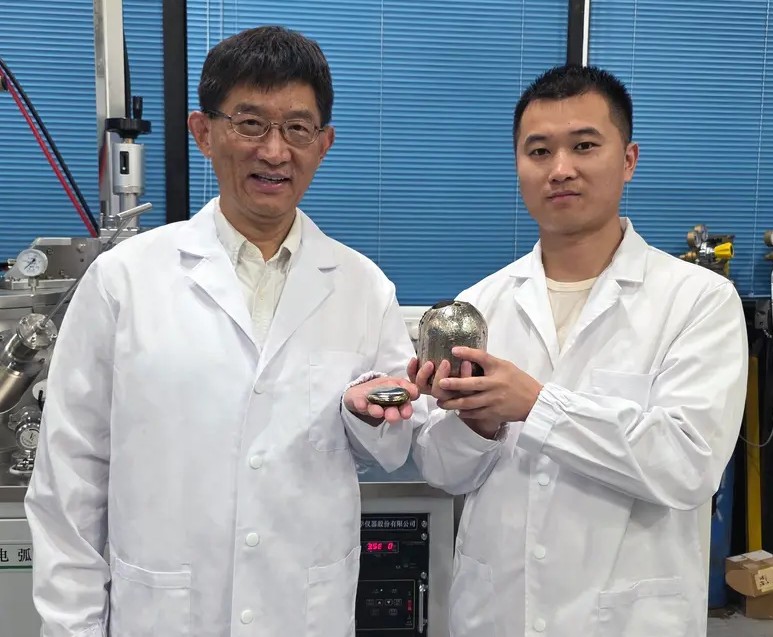

The team, led by Professor Sun Qingping and Research Assistant Professor Li Qiao from HKUST’s Department of Mechanical and Aerospace Engineering, fabricated a [100]-textured Ti₇₈Nb₂₂ martensitic polycrystal. When subjected to linear elastic deformation, this material exhibits a reversible temperature change of 4–5 K—significantly higher than the typical 0.2 K observed in conventional metals. Remarkably, this alloy achieves approximately 90% of the Carnot efficiency limit in a heat-pumping cycle, making it highly competitive with refrigerants used in commercial vapor-compression heat pumps.

The implications are far-reaching. In HVAC applications, systems based on this material could reduce dependency on harmful refrigerants like hydrofluorocarbons (HFCs), which are being globally phased down under the Kigali Amendment. In data centers, vibration-free solid-state cooling could improve energy efficiency and reduce maintenance. In automotive sectors, where waste heat management is vital, compact elastocaloric units could eventually replace bulky, failure-prone radiator systems.

From an engineering perspective, the use of Ti-rich NiTi alloys represents a significant advance in materials science. These alloys offer both high latent heat and mechanical durability and can be manufactured using existing metal-forming techniques. The next step involves scaling the technology into multi-stage thermal modules and pairing it with efficient actuators for practical deployment.

As electrification expands across sectors, the need for efficient, clean thermal control is only increasing. HKUST’s elastic alloy breakthrough doesn’t just improve a component—it redefines how engineers can think about heating and cooling. The future of thermal energy management may not be spinning in compressors, but stretching silently in high-performance metals.