Robert Stirling, a clergyman from Scotland patented the Stirling engine in 1816. Over two centuries since its inception, the engine has seen little application despite numerous advantages. The engine has four main components. A heating chamber, a cooling chamber, heat exchanger and crank piston links. Robert Stirling produced the first functional engine in 1818. It was used to pump water out of a quarry. It was initially called the hot air engine but is now referred by its inventors name.

Stirling engines can be designed in many simple shapes. There are two main advantages of Stirling engine that set it apart from other engines. Firstly Stirling engines have a closed system so they do not need to breathe in or exhale air. This property can be appreciated in confined environment like a submarine where amount of air has a premium. Secondly the heating portion of the engine be kept separate to the cooling section, meaning the engine can be designed with extreme flexibility. Furthermore, as combustion does not occur at all in the Stirling engine cycle, it can be made with a variety of materials. Although the engine does require high conducting materials in its hot and cold sections.

A more modified and improved version of the Stirling engine surfaced in 1846, patents of which were filed in the name of Robert and his brother James Stirling. Compared to steam engines the Stirling engine could reach efficiency of over 50%. Efficiency of a Stirling engine increases with the increase in temperature difference between the hot and the cold source. It also increases with the increase in operating temperatures. The working fluid inside the engine is pressurized to a level above the ambient pressure.

The Stirling Engine does not require combustion (that results in gas expansion) inside the engine. High grade fuels like petrol and diesel are formulated such that they leave the least amount of particulates inside the engine if at all. The advantage of a Stirling Engine is that even poor grade fuel can be burned externally and the heat supplied to the engine. Thus low grade coal, wood, straw and biomass can be used. Anything that burns can be used as a heat source.

The Stirling Engine for over a century has been mainly part of small domestic applications. However with an increase in renewable energy and an interest to achieve zero carbon economy, Stirling engine are back in focus.

Kits

Stirling Engines are extremely simple devices and therefore can be assembled easily. There are kits available on the internet for Stirling engines for various sizes and can be purchased for as low as £10. The simplicity of the design allows it to be assembled by even a layman. Some of engines are so sensitive that they can run from the heat off the palm of hand or the heat coming off a teacup. These engines are great for classroom demonstration. Note that Stirling engines with high sensitivity have been developed that can operate 0.5 °C. A number of videos on YouTube can be found in which step by step guidance is available for constructing an engine from ordinary parts found in household. These parts often include simple as steel wool, rubber balloon, metal wire and soda cans.

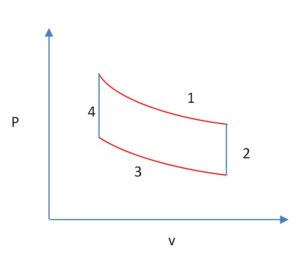

Thermodynamic cycle.

The strokes of the Stirling Engine can be classified into four processes:

- Isothermal Expansion

- Iso-choric heat removal

- Isothermal compression

- Constant volume heat addition

This has been represented in the diagram below. The area under the curve “1” minus the area under the curve “2” equates to the the work done.

There are three different configurations of Stirling engines depending how air is shifted between hot and cold areas. These configurations are called Alpha (two cylinders) Beta (single Cylinder) and Gamma (two cylinders). A variety of working fluids have been tested including phase change materials. Air however is most commonly used because of its abundance. Helium, Hydrogen, Nitrogen, Methane and Ammonia have also been used. All gases are lighter than air. Liquid Piston Stirling engines also carry benefits and are being studied. Hydrogen due to its low viscosity and high thermal conductivity is ideal for the thermodynamic process, however preventing hydrogen from leaking is difficult and sealing can increase the cost. Due to its low power density Stirling Engines are mostly used in static application.

Interesting Applications of Stirling Engines

NASA program (Automotive Stirling Engine Program) lead to the development of Stirling Engine cars in the 1970’s. The AMC Spirit was used for the experimental Stirling Engine alongside Dodge D-150, Chevrolet Celebrity and GM G-Chassis cube van, All cars were extensively tested for 50,000 miles. The AMC Spirit was able to achieve average efficiency range between 18 and 28.5 miles per gallon. However due to lack of commercial interest and funding cutbacks the program was rolled back. There were two main reasons for the subdued enthusiasm by the automakers. Firstly the engine required time for warming up and change of speed also took time.

In the 1980’s, Kockums a Swedish company, fitted a Stirling engine in Royal Swedish Navy submarine Näcken. Three other submarines in Swedish Navy since have installed this engine. For submarine propulsion, the Sterling Engine helps to burn liquid oxygen stored in cryogenic tanks with diesel. The combustion as result produces higher pressure inside the combustion chamber compared to the surrounding water pressure where the gas is discharged. Thus the difference in pressure provides the propulsion. Stirling Engine have also been used by the Australian Navy for the displacement of 3000 ton submarine. Post world war 2, Philips Electronics also developed a 90 hp Stirling engine for marine use.

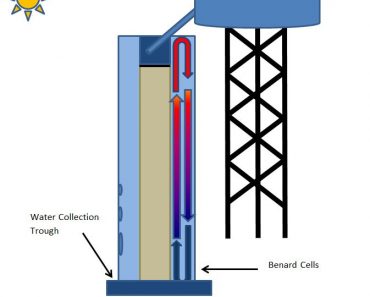

Over the last decade, Solar Stirling dish systems have become extremely popular option for renewables in arid areas with ample solar radiation.

Stirling engines are flexible and can be used for both heating and cooling purposes. Therefore its application as a heat pump is natural.

An extremely interesting application of the Stirling Engine is cryo-coolers. Stirling Engines can be used to produce extremely low temperatures (below -150 °C). The low temperature allows its use in numerous other application like liquefying gases to making metals superconductors.

Stirling Engines are also useful for Micro CHP (Combined Heat and Power) applications. Small waste fuel incinerators can be used in conjunction with Stirling engines to produce electricity with waste management.

In space, the temperature of the satellites vary greatly depending upon the position. The satellite portion facing the sun is at a much higher temperature compared to the portion looking into deep space. For this reason, Stirling engines have been considered as a source of power in satellites along with solar panels.

References

Please feel free to share this article using the button below.