Contents

Till the year 2008, more than 80% of the electric cars in USA were conversions done privately. The reluctance of car manufacturers to roll out electric vehicles pushed green car enthusiasts to take it upon themselves to produce vehicles that were emission free.

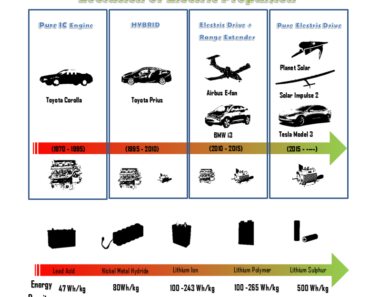

Contrary to the popular belief, the earliest cars to appear on the road had an electric drive till they were eclipsed by the I.C engine vehicles. Battery technology advanced slowly and as a result, electric cars were confined to golf buggies and milk floats.

The technology for electric drive has existed for almost a century and therefore people looking to do an EV conversion will find the required components available. In fact, through EV conversions, one can breathe new life into classic cars that are rusting away because their I.C engine parts are unavailable.

However, before embarking on a EV conversion project, one must realize that there is a steep learning curve involved and knowledge, skills and resources are required. Not to mention the will power in spades. This article aims to provide an idea of the nature and the scale of the project, i,e an EV conversion. The following considerations for are mandatory:

Stage 1: Design Concept

The first stage of EV conversion is the conceptual design. The user has to decide the purpose EV. Is it being designed for drag race? Is it being designed inter-city commuting? or will the car be used for long distance commuting?

Each type of requirement would dictate the need for different set of components and different design strategy.

For example, if the car is being used for a drag race, the motor / motors that need to be fitted will have to be brush-less DC motors.

DC motors cannot be beaten for torque at wheels when the car starts from rest. On the other hand if torque is required at high -rpm is required such as when ascending on a hilly terrain at speed than AC motors perform better.

Similarly, if long distance commuting is required from the EV than it is ideal to choose a vehicle that has a low kerb weight, small frontal area, low Coefficient of drag and still has enough room for the batteries. The Toyota MR 2 Mark 2 was one such vehicle. Not only it was very aerodynamic but it also had three compartments where battery could be stored.

Similarly, the Audi A2 is a great choice for EV conversion because of its sleek design and abundant space for batteries.

Stage 2: Preparation of Conventional Car for EV drive

Once an existing car is selected for conversion, it’s engine needs to be removed. For this purpose it is important to have a dedicated garage space. The removal of engine requires not only skills but also tools such as a hoist or a garage swivel crane. Similarly, ramp may be needed at several stages of the project. Therefore high mechanical skills are required other than the tools/ resources. There is no shame in asking your local garage for removing the engine as they will do it quicker and safer.

The fuel tank, radiator and other auxiliary components supporting the I.C engine also need to be removed to create space and reduce weight.

Stage 3: Procurement

EV conversion require just not a motor and batteries, but many other components. Some of them are listed below:

- Motor

- Controller

- Wires , Bus Bars

- Contactor Switches

- Emergency switch

- Battery Management System

- Controls devices (Accelerator/ Throttle that outputs electrical signals)

- Electric vacuum pump for brakes

- Relays, Switches and Fuses

- Connectors

- Vibration damping devices

- Fire safety components

Some of the components can be salvaged from the local car breaker . However, most of these components will have to be purchased. Although good condition motors both AC and DC are available at the local scrap yard but most of the times they cannot be used as their respective controller is not available.

A good source for motor controllers is Paul and Sabrina’s website.

Stage 4: Assembly

Attaching the motor to the drive shaft is not an easy process and requires specialist equipment. Similarly parts to form a joint may have to be designed and fabricated for attaching the motor in place of the engine. At times, even welding might be needed. Again the local garage or machine shop can help at this stage. Batteries similarly may have to be spread out in two or more banks to keep the weight distribution even.

Measures will have to be taken to keep the elements particularly moisture out of the battery pack. At the same time provision for gas venting inside the battery pack has to be made.

Stage 5: Safety Considerations

The battery pack can be dangerous if not handled properly. The chemicals inside the battery are flammable. Similarly electrical fire safety equipment also needs to be considered. Circuit isolation switches should be part of the design. Vibration damping and a proper cooling mechanism of battery pack will enhance the life of the batteries.

It should be clear from the article that EV conversion may sound an exciting project but it requires a thorough design, in addition to skills and resources. The result is equally rewarding. After all there is nothing like driving away a car designed by oneself.