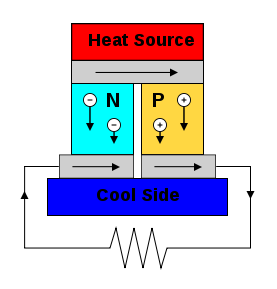

Thermoelectric Generator or TEG in short is a device that makes use of temperature differential across different junctions of a thermocouple to generate electricity. It is also sometimes called a Seeback generator as it is based on a phenomenon discovered by German physicist Thomas Johann Seeback in 1821. The device is as simple as a diode.

The biggest advantage of a TEG is its solid-state construction that has no moving parts. This means they are more reliable compared to other electricity generation systems like heat engines or dynamos. They typically come with a service life of 20 or more years. This simple device often excites students and eco –enthusiast, who may think of it as the Holy Grail to the energy problems.

It should be understood that when working with low grade energy, such as heat at a small temperature differential, the conversion into useful energy comes at the price of high energy wastage i.e. low system efficiency. It is therefore common to find TEGs with maximum efficiencies hovering around 3-5%. Nonetheless in applications where heat loss in inevitable, they can be valuable in recouping some portion of the wasted energy.

Small scale palm size TEG can generate up to 5W. They are scalable and the larger models can even charge a 12 V or a 24 V battery. They can be purchased in sizes up to 30W, 60W, 120W and 220W outputs. Note that larger TEGs are not completely solid-state and employ moving fluid on their cooling side.

There have been several patents filed for TEG to be used in conjunction with Solar cells. It should be noted that single layer solar cells are able to convert only a portion of the light that falls on them. The remaining portion of light is converted into heat. By using TEGs in tandem with solar cells, electricity output can be increased.

Because of the relatively poor efficiency, they are only economically feasible when temperature difference of around 200°C is available. This follows thermodynamics law which dictates that the higher the temperature difference between the hot and cold sources, the more the system efficiency.

To withstand high temperatures (up to 250°C), the two junctions of the TEGs are made of ceramic. Although the efficiency is higher at higher temperatures but the internal resistance within the elements and the connecting wire also increases. Teflon is normally used as an insulator on the connecting wires in TEG to enhance durability at high temperatures.

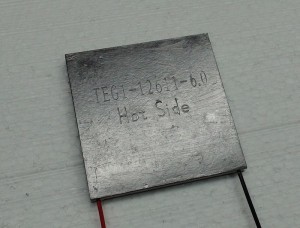

TEGs are often confused with Thermoelectric coolers (TEC), which in fact operate reciprocally using the Peltier effect. The construction of TEG is different to TEC. Thicker but more flexible wires can be spotted on TEC while the element size on the inside is much smaller.

The price for TEG has reduced overtime and can be bought for as little as £3. When purchased in bulk quantities, discounts also apply. They can be purchased from electronic stores; however it is much cheaper to buy them from online. Resellers, particularly from China sell them at the lowest price.

Specs of a small scale TEG are given below:

Material: Ceramic / Bismuth Telluride

Temperature differential (°C)/Open-circuit Voltage(V)/Current(MA): 20/0.97/225 40/1.8/368 60/2.4/469 80/3.6/559 100/4.8/669

Module weight: 25g

Module size: 4 * 4 * 0.4cm (L * W * H)

The specifications of a typical large scale TEG are given below.

Power: 100W

Output voltage: 24 V

Dimensions: 600 x 146 x 57 mm

Weight = 7.8 Kg

Hot side Temperature 270 °C